Thank you

Your request has been sent successfully

| Engine manufacturer | Deutz |

| Motor type | TCD 3.6 S5 |

| Cylinder | 4 |

| Drive output | 100 kW |

| Drive output | 136 PS |

| At max. rpm | 2.300 U/min |

| Cylinder capacity | 3.621 cm³ |

| Type of coolant | Wasser/Ladeluft |

| Exhaust standard level | V |

| Exhaust aftertreatment | DOC/DPF/SCR |

| Engine manufacturer | Deutz |

| Motor type | TCD 4.1 S5 |

| Cylinder | 4 |

| Drive output | 156 PS |

| At max. rpm | 2.300 U/min |

| Cylinder capacity | 4.038 cm³ |

| Type of coolant | Wasser/Ladeluft |

| Exhaust standard level | V |

| Exhaust aftertreatment | DOC/DPF/SCR |

| Operating voltage | 12 V |

| Battery | 185 Ah |

| Alternator | 120 A |

| Operating weight | 11.210 kg |

| Tipping load with bucket – machine straight, loading frame horizontal | 6.594 kg |

| Tipping load with bucket – machine pivoted, loading frame horizontal | 5.871 kg |

| Tipping load with bucket – machine straight (extended) | 3.495 kg |

| Tipping load with bucket – machine pivoted (extended) | 3.112 kg |

| Tipping load with pallet fork – machine straight, loading frame horizontal | 5.775 kg |

| Tipping load with pallet fork – machine pivoted, loading frame horizontal | 5.142 kg |

| Tipping load with pallet fork – machine straight (extended) | 3.265 kg |

| Tipping load with pallet fork – machine pivoted (extended) | 2.907 kg |

| Driver's cab | Kabine |

| Tank capacity for fuel | 140 l |

| Tank capacity for hydraulic oil | 125 l |

| Tank capacity for urea solution | 12 l |

| Type of drive | hydrostatisch |

| Drive unit | Gelenkwelle |

| Speed levels | 3 |

| Axle | PA 1900 |

| Travel speed Standard | 0-20 km/h |

| Travel speed Option 1 | 0-30 km/h |

| Travel speed Option 2 | 0-40 km/h |

| Operating brake | Lamellenbremse in der Vorderachse über Gelenkwelle auf Hinterachse wirkend |

| Parking brake | Elektro-hydraulische Lamellenbremse mit Federspeicher in der Vorderachse, über Gelenkwelle auf Hinterachse wirkend |

| Differential lock | 100% Vorderachse + Hinterachse |

| Drive hydraulics working pressure (max.) | 480 bar |

| Work hydraulics discharge volume (max.) | 150 (180) l/min |

| Work hydraulics working pressure (max.) | 250 bar |

| Lifting cylinder | 1 |

| Tipping cylinder | 1 |

| Quick change system | hydraulisch |

| Steering type | Hydraulische Knicklenkung mit Pendelachse |

| Steering cylinder | 2 |

| Oscillating angle of the rear axle | ± 12 Grad |

| Average sound power level LwA (cabin) | 100,7 dB(A) |

| Guaranteed sound power level LwA (cabin) | 102 dB(A) |

| Specified sound pressure level LpA (cabin) | 70 dB(A) |

|

FSD = Fahrerschutzdach DPF = Dieselpartikelfilter DOC = Dieseloxidationskatalysator SCR = Selektive katalytische Reduktion Kipplastberechnung nach ISO 14397 |

|

|

When comparing tipping loads and lift capacities from different manufacturers, make sure that they have been determined in accordance with the ISO 14397-1 and 2 standards!

General Information

Attention: The tipping load changes depending on the various equipment features of a machine (e.g. operator’s platform/cab, rear weight, engine, tires, etc.). The net weight of the various attachments naturally also plays a role here.

Important to note

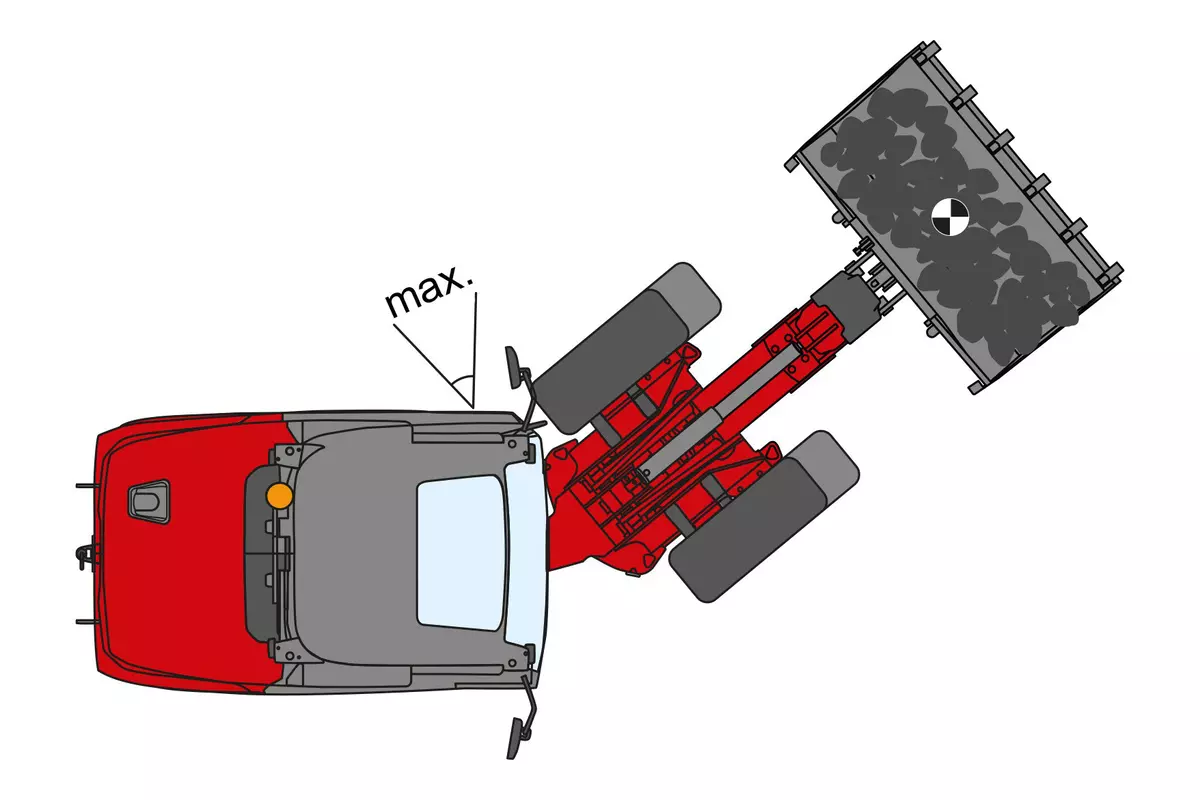

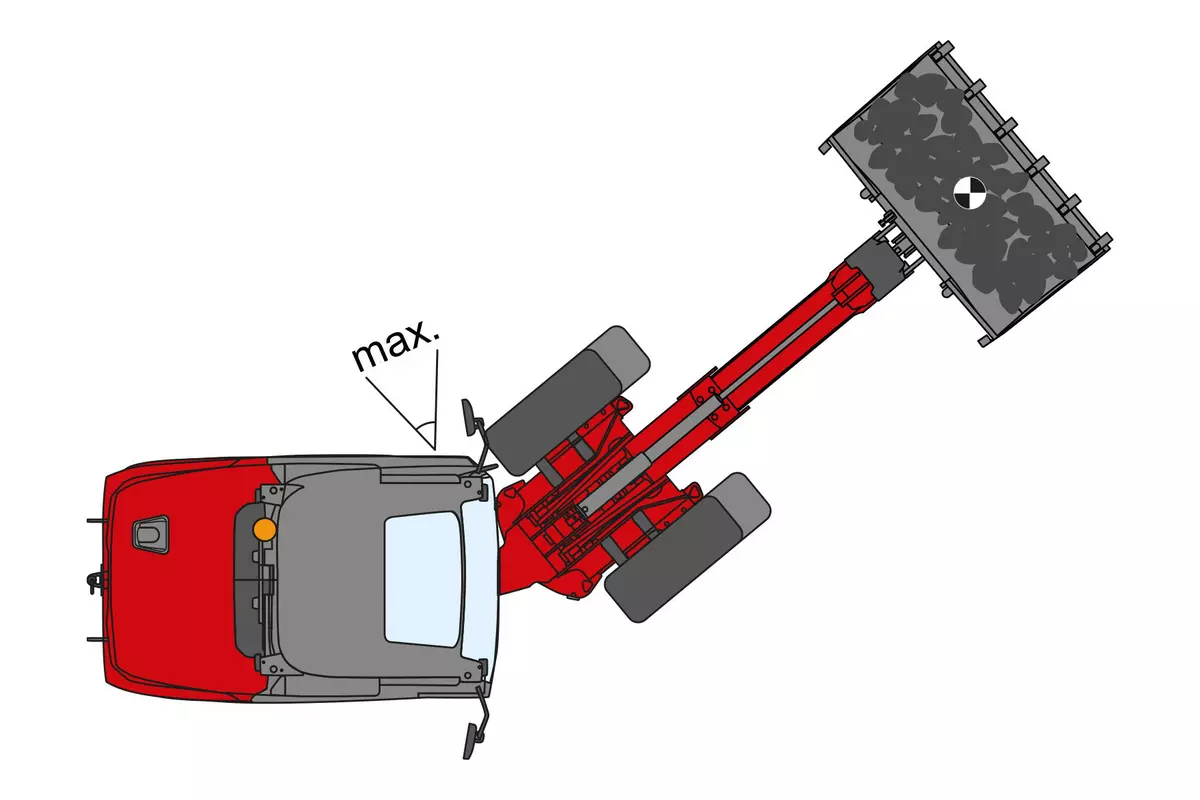

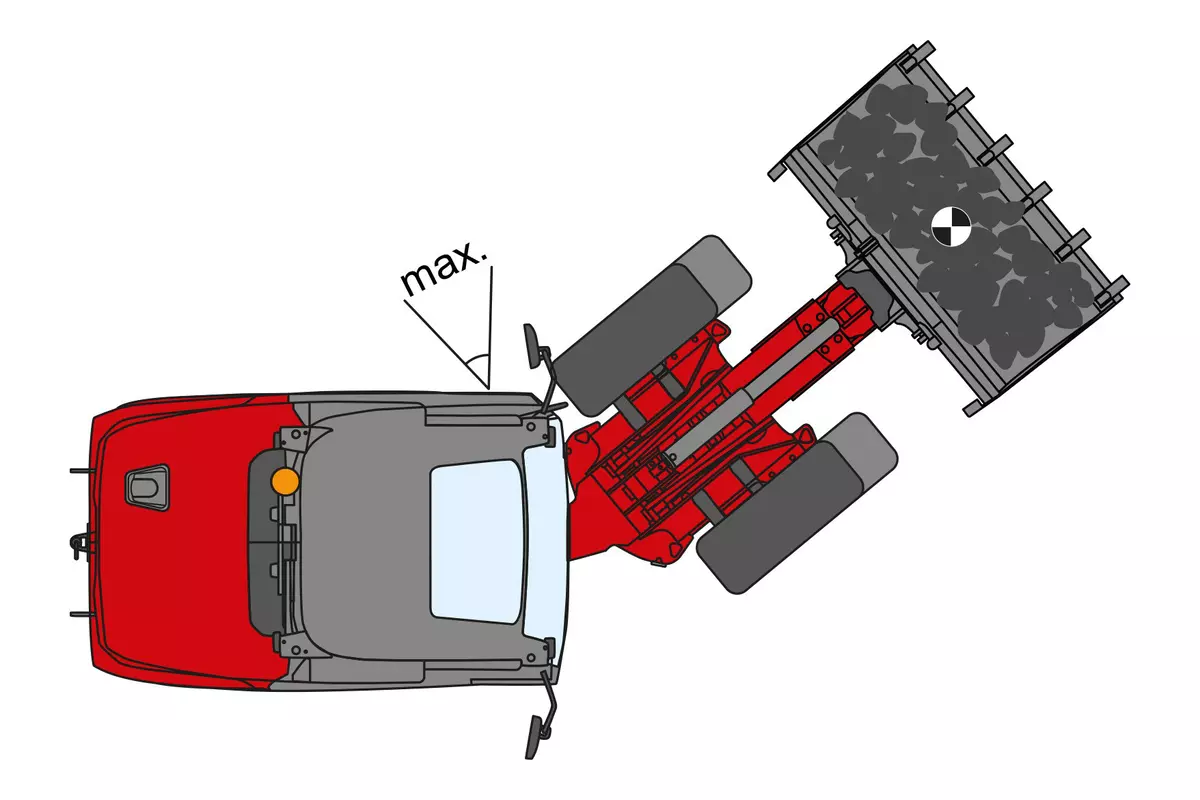

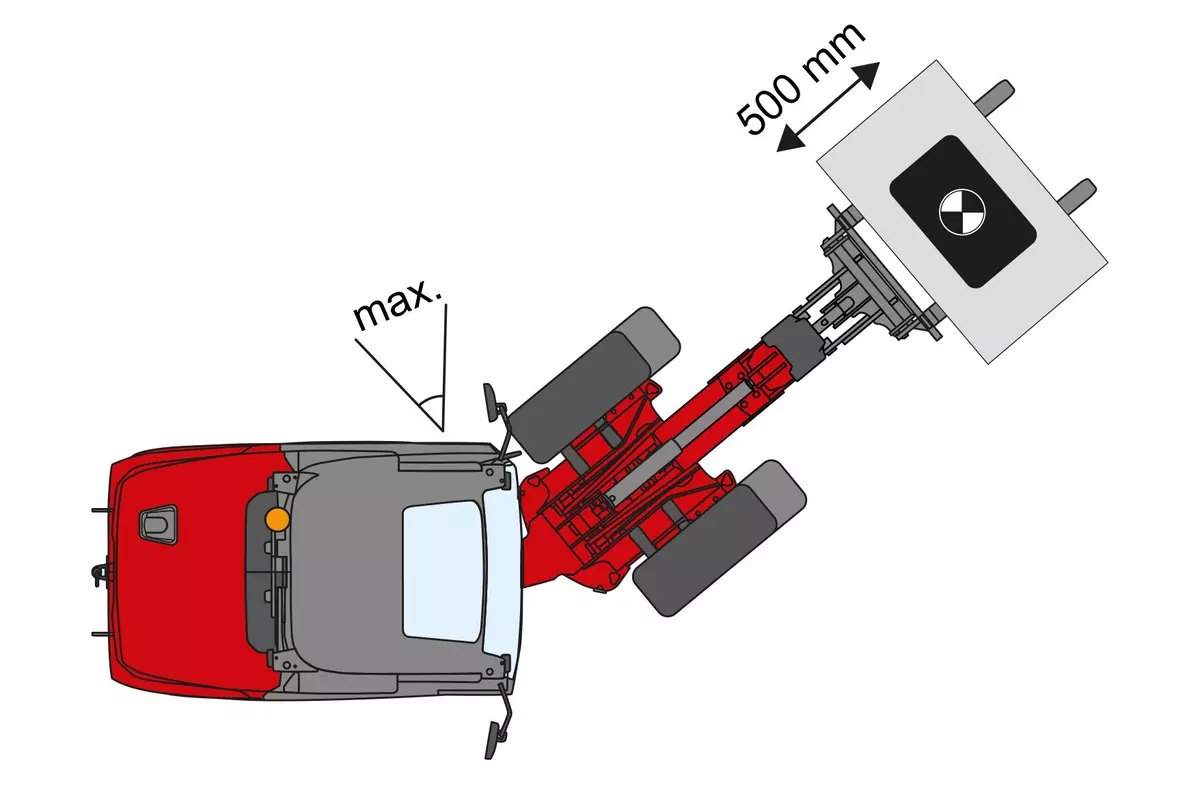

Good to know: Tipping loads determined in the buckled state are highly dependent on the buckling angle of the machine. Weidemann determines these values in the fully folded state. When comparing with other manufacturers, please note the kink angle used!

When comparing tipping loads and lift capacities from different manufacturers, make sure that they have been determined in accordance with the ISO 14397-1 and 2 standards!

General Information

Attention: The tipping load changes depending on the various equipment features of a machine (e.g. operator’s platform/cab, rear weight, engine, tires, etc.). The net weight of the various attachments naturally also plays a role here.

Important to note

Good to know: Tipping loads determined in the buckled state are highly dependent on the buckling angle of the machine. Weidemann determines these values in the fully folded state. When comparing with other manufacturers, please note the kink angle used!

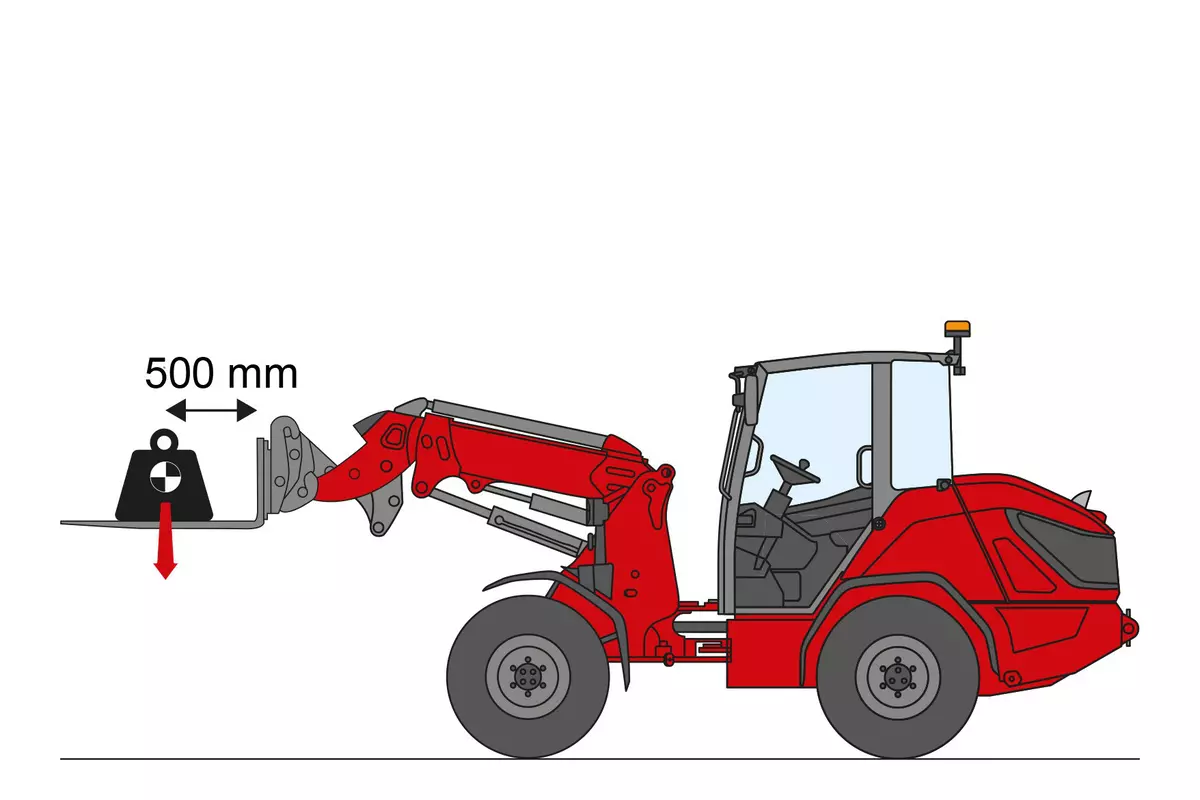

Weidemann determines these values in accordance with the standard at the center of gravity of the bucket – not at the pivot point!

|

|

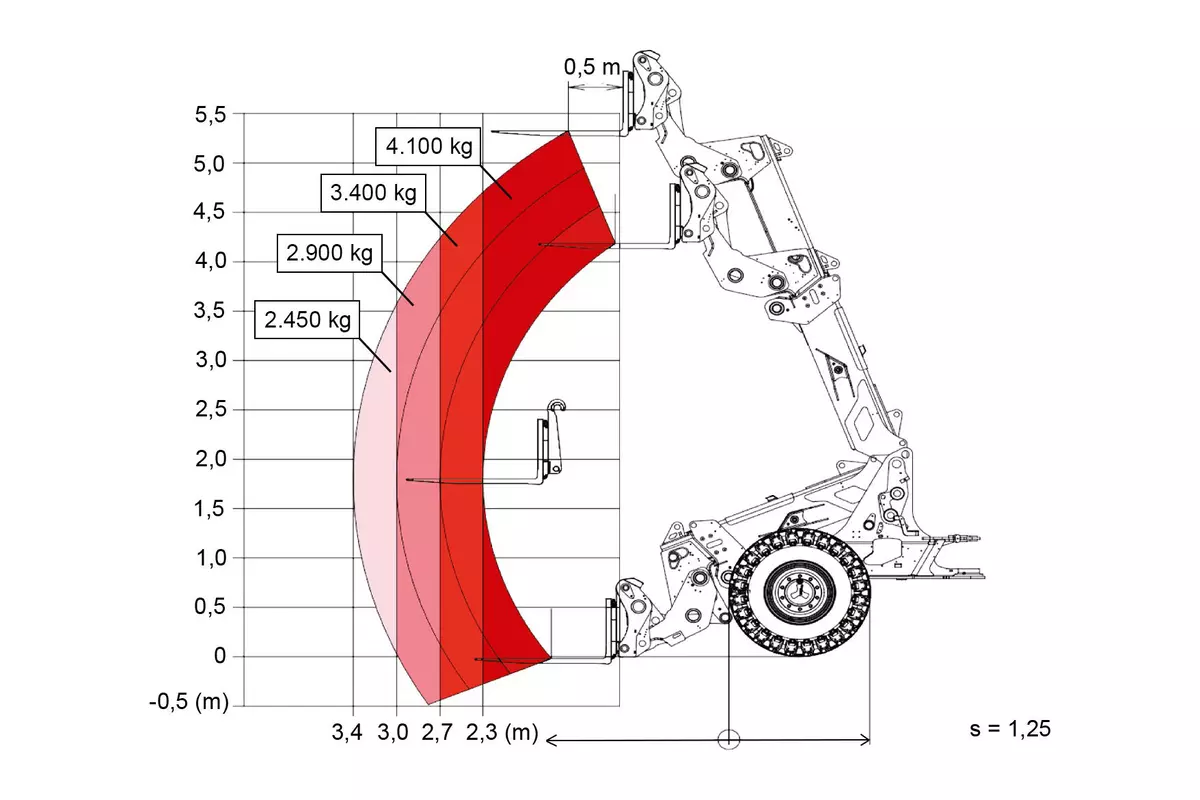

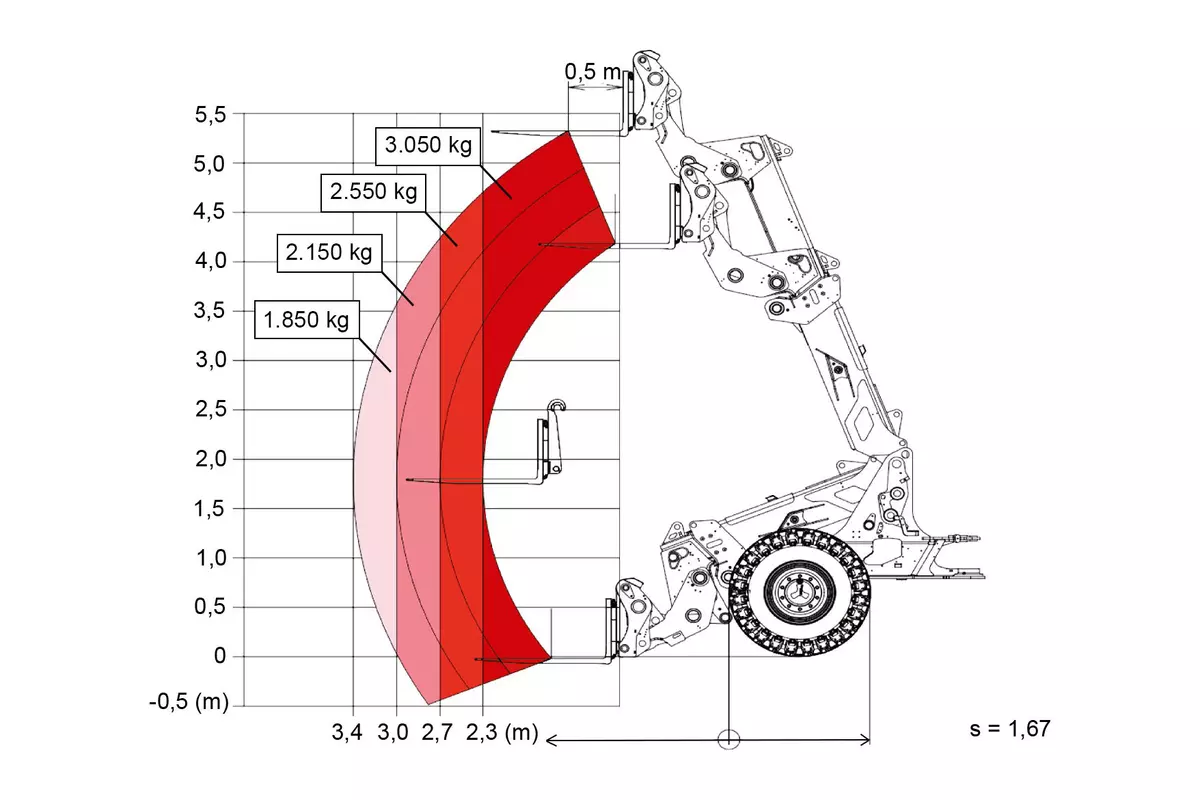

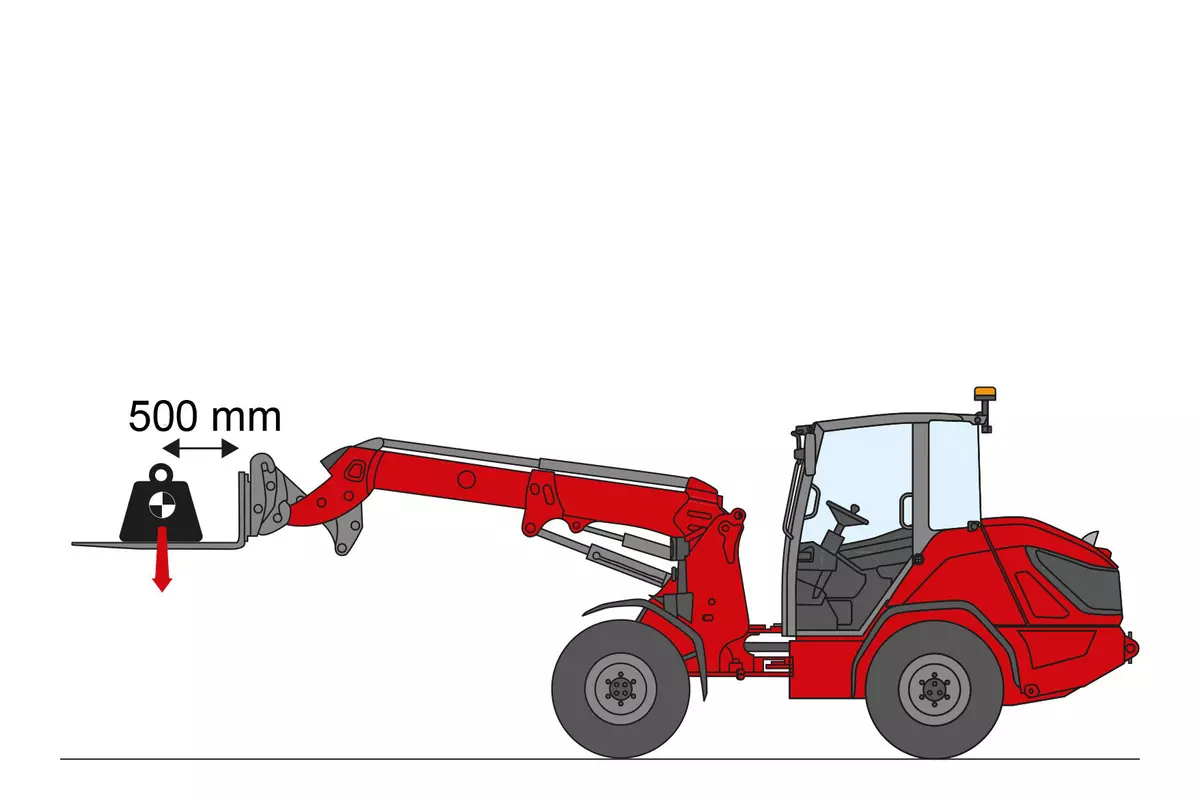

The maximum lift capacity in the bucket’s center of gravity is measured by Weidemann as follows:

|

|

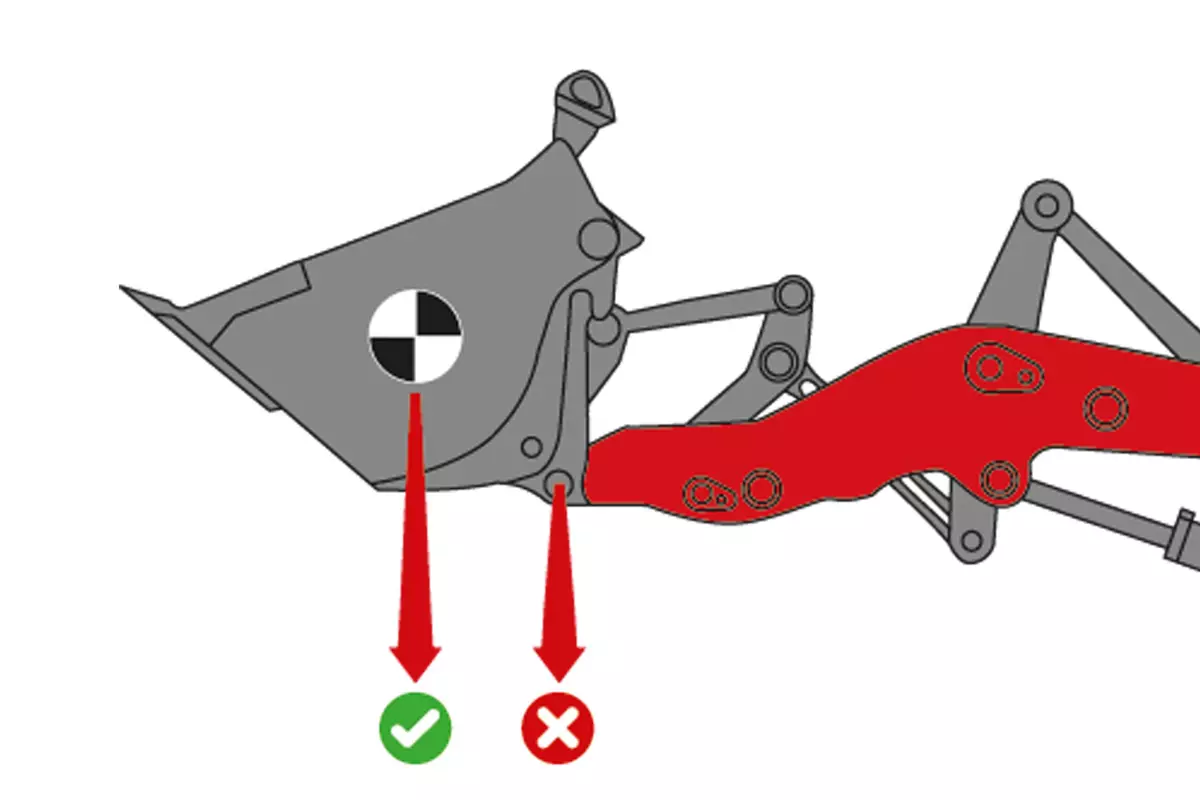

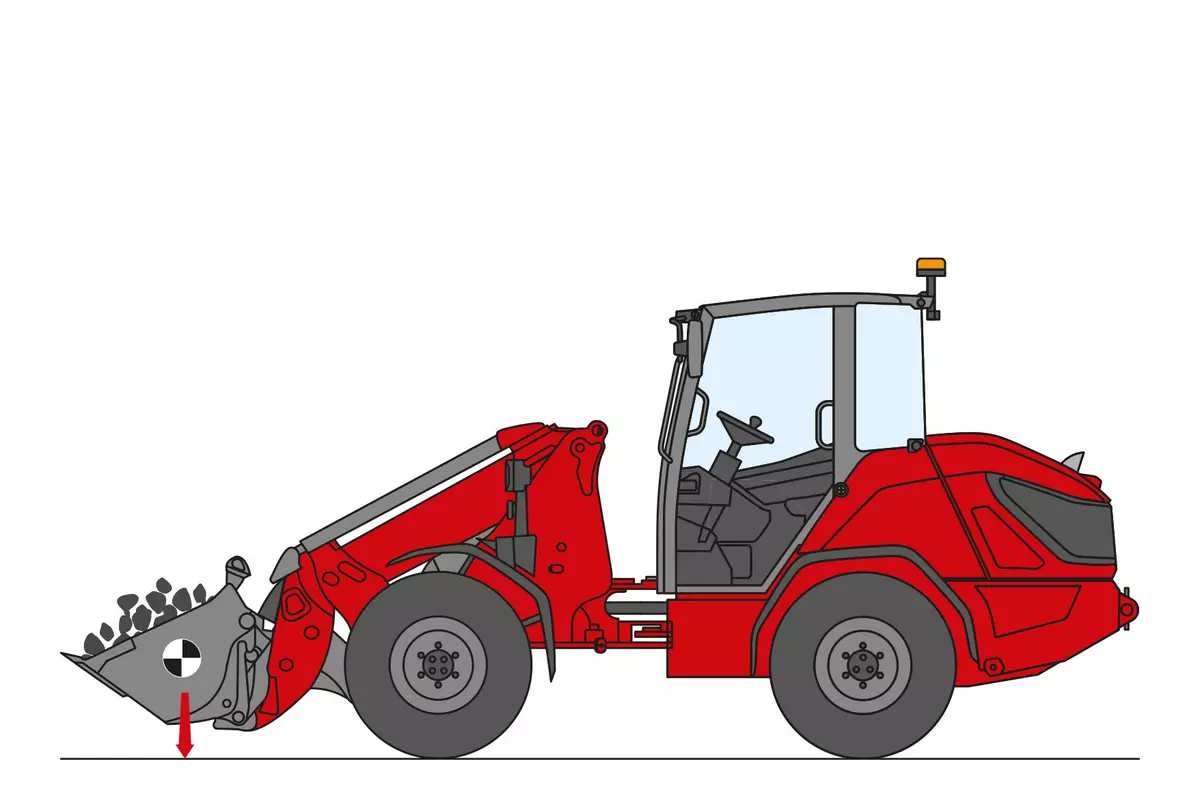

The maximum tear out force on the below bucket edge is measured by Weidemann according to the standard ISO 14397-2, this means:

|

|

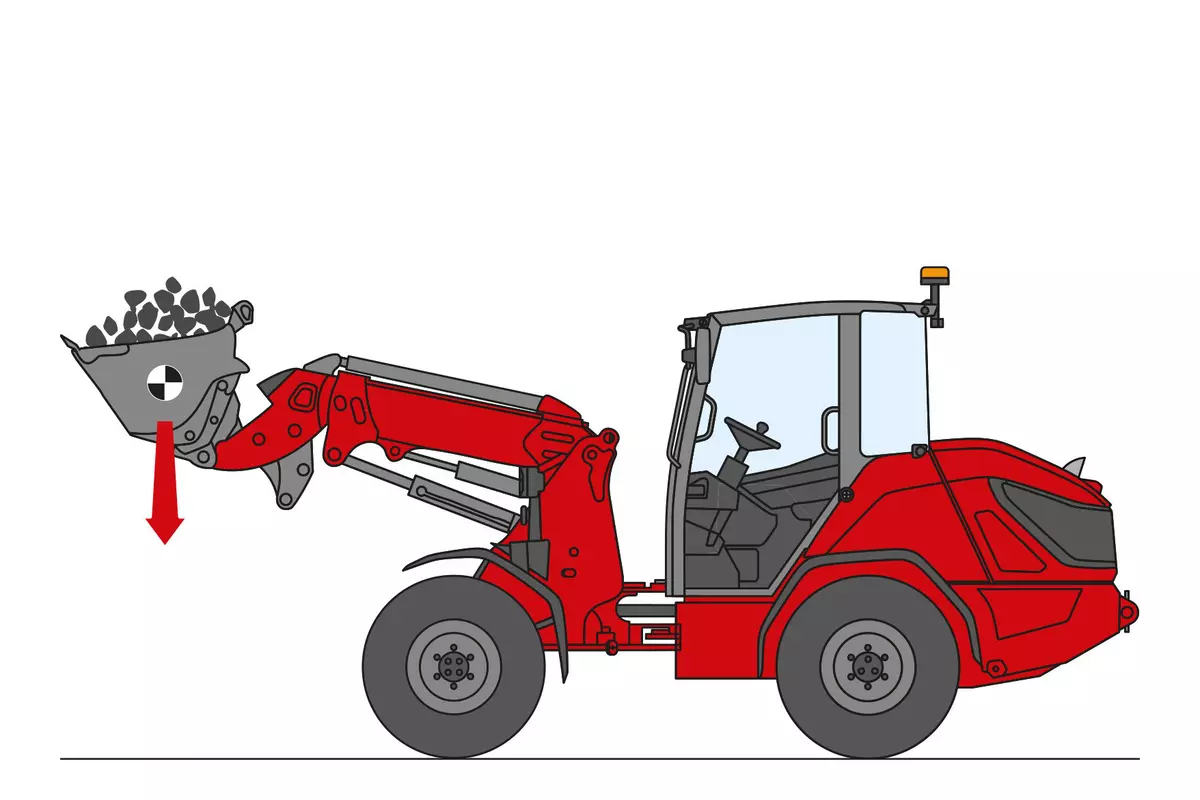

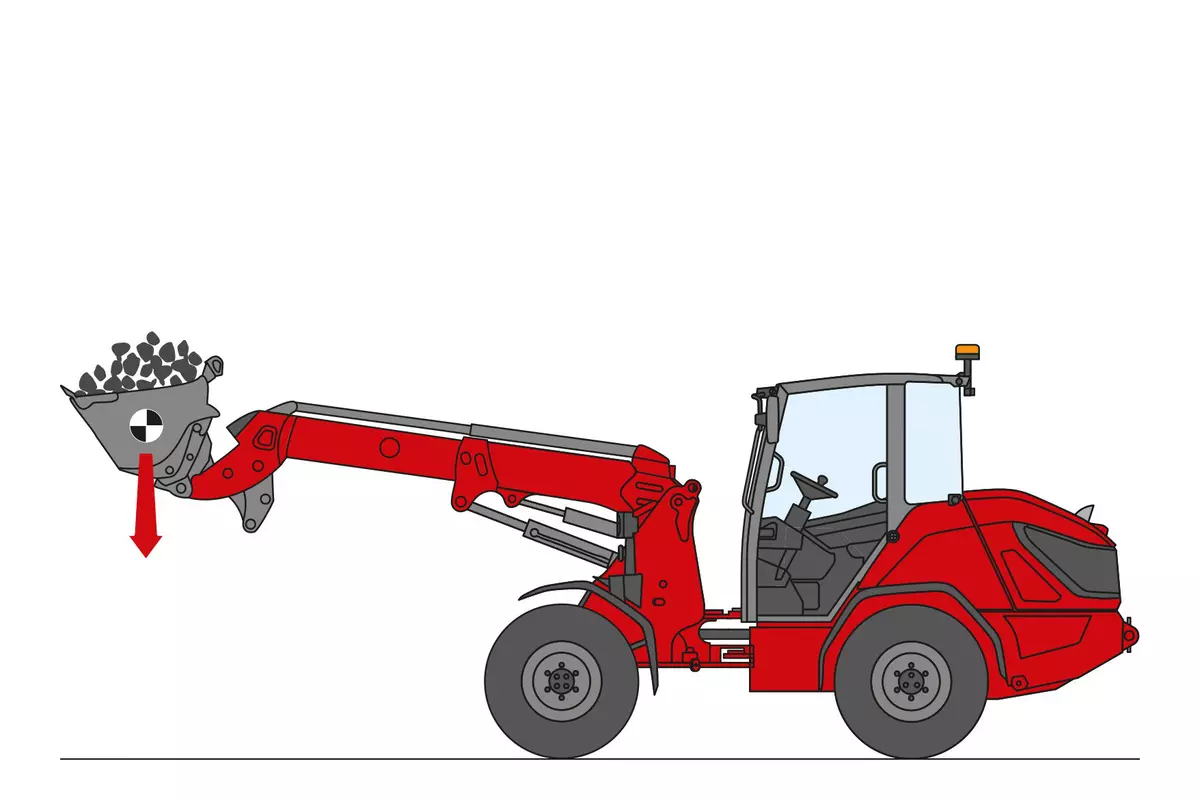

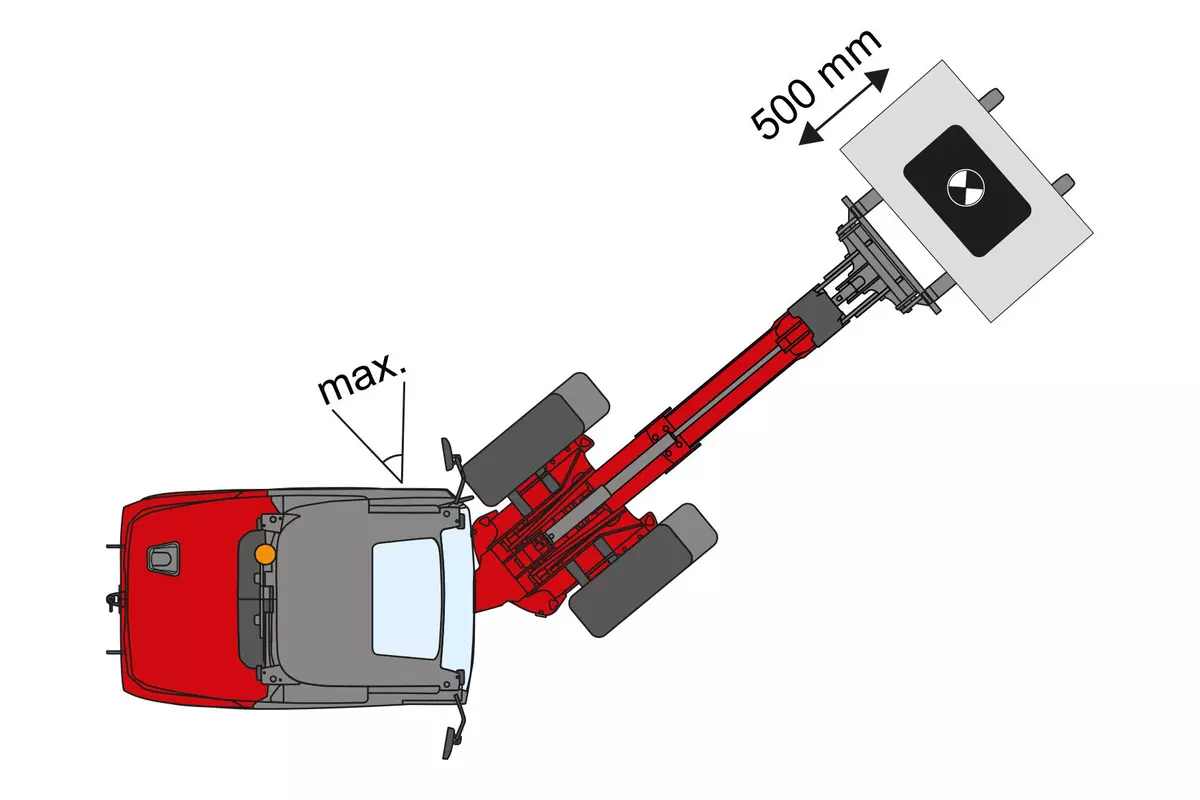

The maximum load weight of a machine is known as the tipping load. This is achieved when the rear wheels of the machine lose contact with the ground. The tipping load is measured by Weidemann according to the standard ISO 14397-1, this means:

|

|

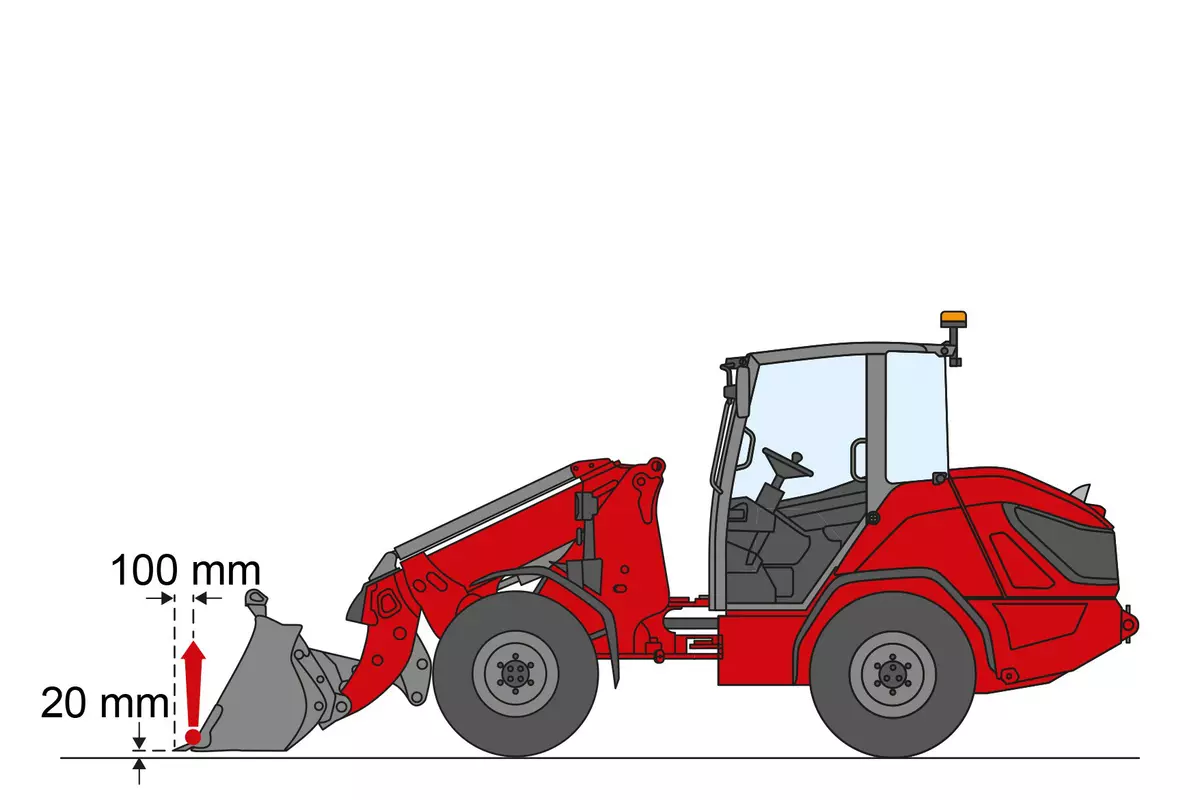

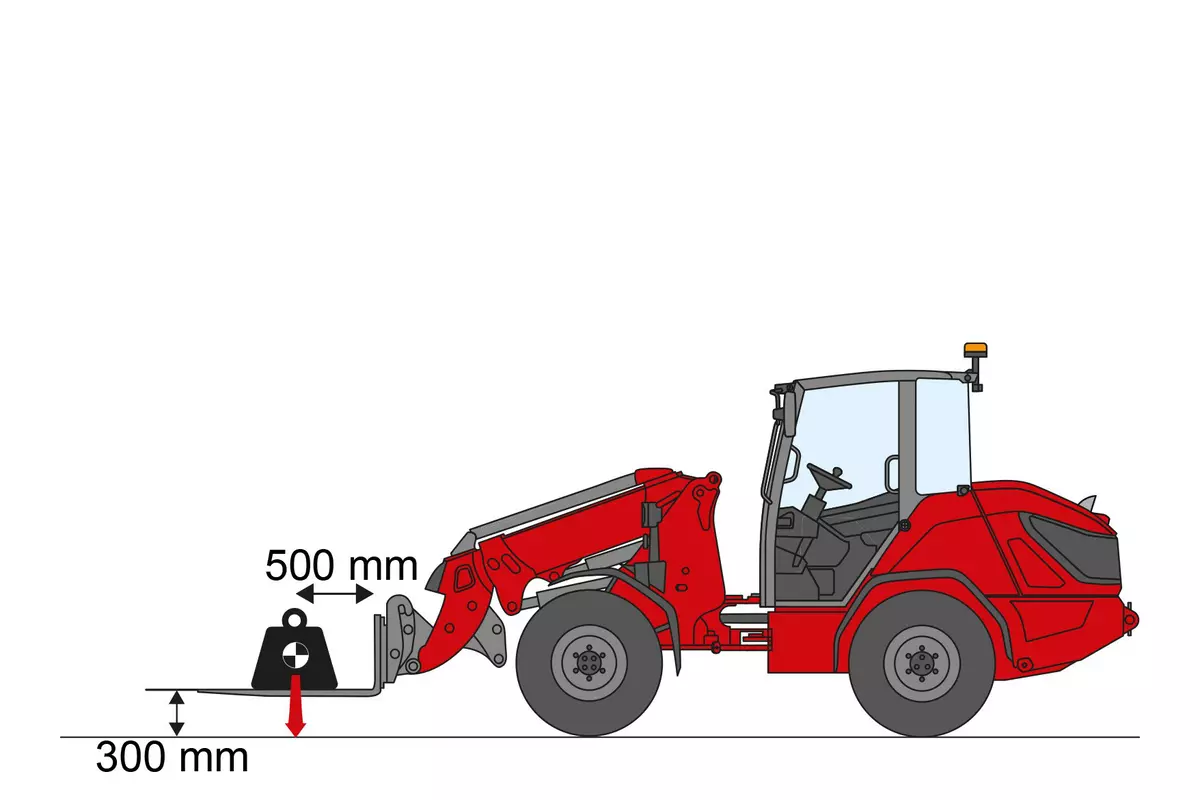

The maximum load weight of a machine is known as the tipping load. This is achieved when the rear wheels of the machine lose contact with the ground. The tipping load in lowest position is measured by Weidemann as follows:

|

|

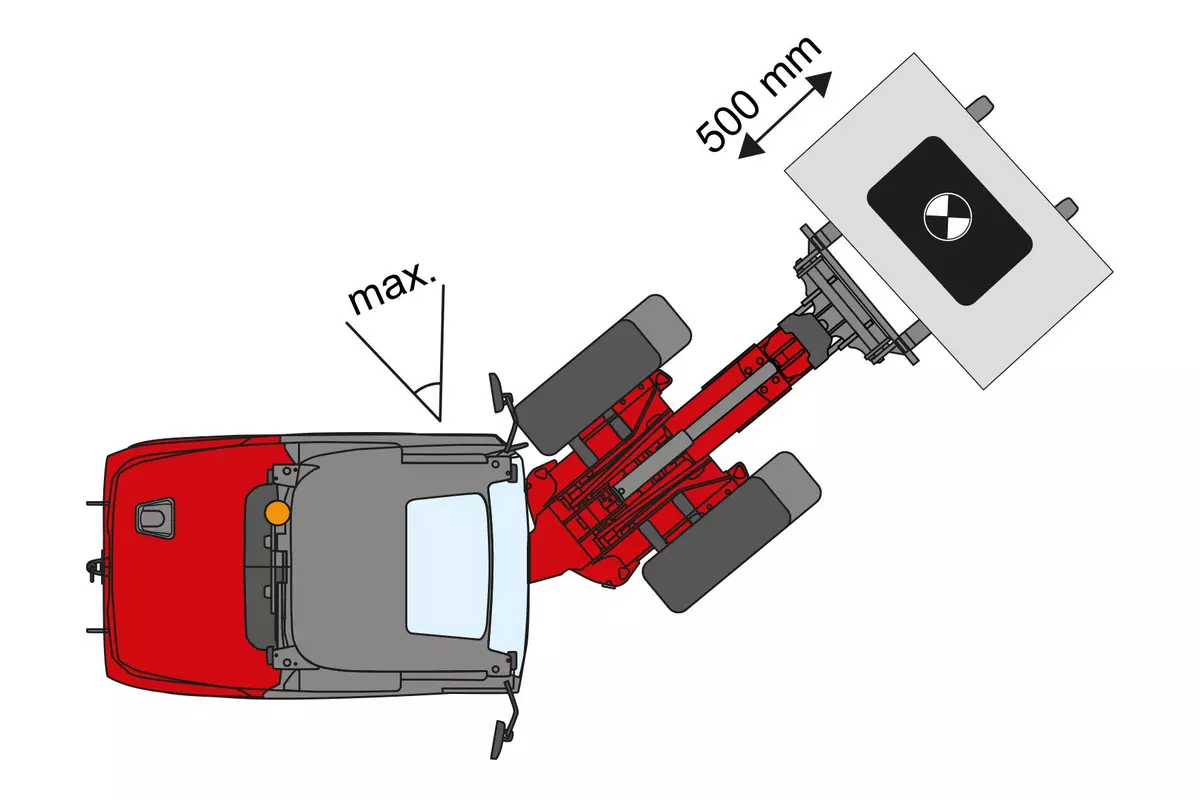

The maximum load weight of a machine is known as the tipping load. This is achieved when the rear wheels of the machine lose contact with the ground. The tipping load is measured by Weidemann according to the standard ISO 14397-1, this means:

|

|

The maximum load weight of a machine is known as the tipping load. This is achieved when the rear wheels of the machine lose contact with the ground. The tipping load in transport position is measured by Weidemann as follows:

|